TFT: The term “Lean, Clean, and Digitally Mean” is at the heart of your conference theme. How do you see these three principles reshaping pharma manufacturing in the next 5 years?

GH: Lean means cutting waste, not people. Clean means precise, repeatable processes. Digitally Mean means using technology with purpose, not just to look modern. In the next five years, the companies that survive and thrive will be the ones that adopt technology after refining their processes, upskilling their teams, and identifying where it actually adds value.

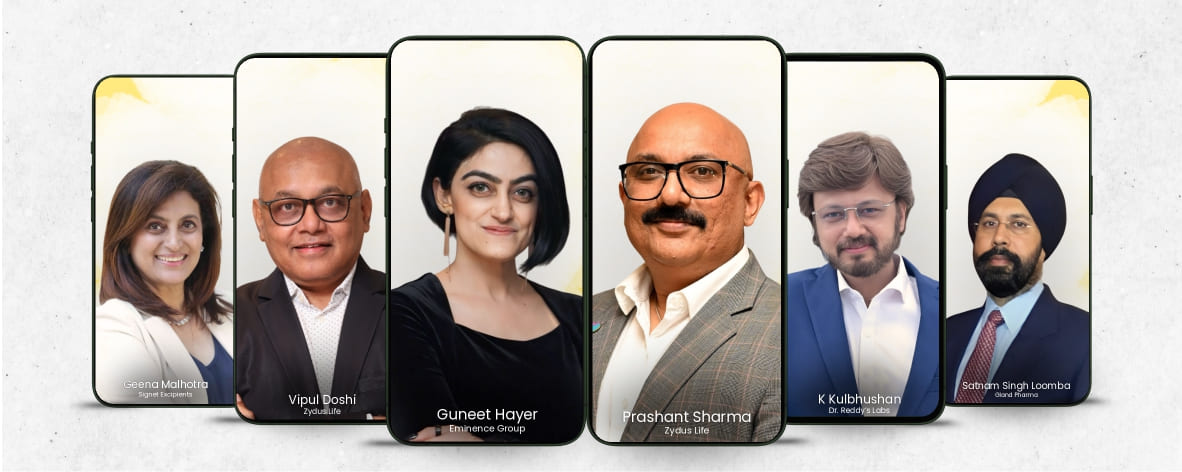

As K Kulbhushan from Dr. Reddy’s warns, “If your process is bad, automating it is only going to create bad productivity at maximum efficiency.” His point is simple: Lean means cutting waste, Clean means flawless processes, and Digitally Mean means purposeful tech. Geena Malhotra added, “Don’t automate for the sake of automation. Work on redundancies and human-error-prone processes first, and ensure the process is robust, reliable, and reproducible before automation.”

Prashant Sharma from Zydus added, “Before you even think of adopting technology, be clear on whether you’re talking about automation, digitisation, or digital transformation. Mixing them up isn’t just a technical error, it’s a costly mistake,” he added, “Without that clarity, you risk buying tools you don’t need, or worse, that your processes can’t handle.”

Satnam supports the aspects of critical thinking with a 4-step procedure stating, “Better control over quality with focus on patient centricity, higher productivity, and measurable workforce skills with growth and ROI should be the guiding anchors for transformation. By categorising initiatives this way, companies avoid wasteful pursuits and focus on changes that truly deliver sustained impact.”

Vipul Doshi mentioned yet another important factor of inclusiveness of operators and supervisors for perfecting the process: “The gap in process refinement cannot be covered if operators and supervisors often don’t fully understand the capabilities of automation or digital transformation. They need to be made part of the journey, not just informed about it. Their inclusion from day zero ensures they don’t just ‘receive’ the transformation, they own it.”

TFT: Many companies rush into automation and AI adoption, sometimes without refining their processes first. What’s your take on this, and how can leaders strike the right balance?

GH: First, let’s clear the fog: automation, digitisation, and digital transformation are not interchangeable. Prashant Sharma stresses that many pharma companies don’t differentiate between the three. Without that clarity, you risk buying tech you don’t need. Geena Malhotra suggests, “Think of automation as something that works without human intervention. Digitisation is information or documents in digital form. But the real game is in making that data readable, usable, and actionable.” She adds, “The gap today isn’t technology, it’s leadership vision, integration, and team training. Strategic foresight of what kind of factory you want in 10 years will shape every decision you make now.” Once you understand the difference, evaluate your needs through Satnam Singh Loomba’s brilliant filter: Critical. Vital. Essential. Desirable. Critical– Directives for quality assurance and control, new Regulatory guidelines are one that cannot be delayed. Vital: Steps that are important but not immediate but near term , focusing on boosting productivity and implementing measurable, planned improvements in various areas. Essential: Investments for future readiness, ensuring the organisation stays at par with industry trends and is prepared for emerging challenges. Desirable: Upgrades that are “nice to have,” often driven by aspiration or “shiny-object syndrome.” These should only be pursued once the first three categories are solidly in place.

TFT: Pharma manufacturing is heavily regulated, yet compliance issues still arise. From your experience, what are the most common pitfalls, and how can companies build a culture of being “always audit ready”?

GH: The problem is too many companies build “new roads during the Olympics,” scrambling to prepare only when inspections loom. True compliance is a culture, not an event. It means embedding regulatory thinking into daily operations, training teams to handle exceptions before they become violations, and ensuring that digital systems enhance traceability and transparency rather than just store documents in a shinier way. Vipul also emphasised on skill development of the workforce, calling it “creating talent from day zero”, and added, “Audit readiness isn’t just about paperwork; it’s about outcomes. First and foremost, decide whether you’re working for the patient or the regulator. Regulators are part of our business, but if we work for the patient first, good procedures and disciplined adherence will automatically keep us compliant. And that’s the thought we need to cultivate in our teams through skill enhancement.”

TFT: Workforce readiness is no longer about basic GMP training. How should upskilling evolve in the digital era, especially with shifting roles, microlearning, and critical thinking skills becoming essential?

GH: While focusing on the important aspect of appropriate training methods in this area, Geena shared: “Training has to evolve. True talent development comes from job rotation, project-based upskilling, simulations, microlearning, and real-time feedback. Otherwise, learning evaporates quickly.” Workforce readiness has moved beyond compliance-based GMP training to a model where adaptability, digital fluency, and problem-solving are core skills. This shift demands continuous upskilling that blends technical expertise with strategic thinking, ensuring teams can not only operate technology but also question and improve it. Satnam says, “You want a workforce that’s hungry for knowledge, not just ticking boxes. We send our people to multiple forums, give them ownership, and bake the learning right into their KRAs. That way, self-learning isn’t optional, it’s measured.” He also makes a strong case for workforce training with a focus on vendor selection and management as well along with other aspects. “If your team doesn’t know what to ask, they’re not ready for transformation,” he says. That means critical thinking, microlearning, and vendor selection skills, so value isn’t lost between hype and implementation. So while we are training our teams to always stay audit ready, are we really creating talent, or just ticking a box on the checklist? Vipul Doshi also highlighted the need for vendor selection and management training in teams and advised developing skills in the workforce to think critically, “Not everything shiny is a diamond. The same ‘shiny toy’ can be a diamond for one company and a disaster for another. We always need to base selection on a solid gap assessment, that’s the talent we need to create in teams for vendor-selection skill development.”

The moral of these guiding steps from leaders suggests one thing: the future-ready workforce is not just trained to operate the tech, but to challenge it when it’s not serving the process.

TFT: In vendor collaborations, there’s often a gap between the promises of tech providers and the real needs of manufacturing units. How can this “value leakage” be avoided?

GH: It starts with a brutally honest needs assessment. Define your goals in business language, not tech jargon. Satnam Singh Loomba said, “Automation is a very expansive subject. In simple words we can say, there is an automated machine that delivers the efficiency, reproducibility and the heart is the software that drives the machine.” To give a solution to this challenge at hand he also proposed that knowing the true problems and evaluating the gap well is critical to find the most apt solution, and added, “With each passing year, Windows versions change, machine firmware upgrades roll out, and older software begins struggling with compatibility and security in organisations where multiple servers and applications constantly communicate. These changes bring significant, often hidden costs in both revenue and CAPEX, impacting ROI over the full lifecycle of systems, he continued, “In organisations with multiple stakeholders; Quality Control, Manufacturing, Utilities, Warehousing, EHS, BMS, and Quality Assurance; each function competes for the same budget. This forces tough prioritisation decisions for CXOs, who must balance immediate needs with long-term growth. In the generics segment, where flexibility and speed in handling multiple products are critical, this becomes even more challenging.” He also presented the way out by re-emphasizing on his theory on guiding these choices, by using four clear classifications: Critical (must act now for quality and control), Vital (boosts productivity and delivers measurable steps), Essential (future-readiness), and Desirable (nice-to-have, but not urgent).

While discussing with Vipul Doshi, he highlighted that mid-size companies sometimes don’t know where to begin, and he added, “The key is to first understand what’s required and what’s not. For example, if you need inventory management, decide whether it needs to be complex or simple. Map the process, clarify expectations, and then plan. Only after this should you choose your vendors.” Involve the actual end-users early, they’ll catch impracticalities that leadership might miss. Train your team to challenge vendor claims, run small pilots, and measure ROI before scaling. And remember: a vendor is a partner, not a magician. In the end of the day if you install a high end machine but remove all its benefits to make it fit your budget, it might fetch poor to average results. Geena Malhotra puts it beautifully stating, “Don’t make a good machine work on average methods. If you compromise on equipment quality, you’re using a Ferrari but only pulling the benefits of a Fiat.”

TFT: The push for productivity often focuses on cost-cutting, but you’ve talked about people and asset productivity too. How can companies increase both without compromising quality?

GH: Vipul Doshi suggested, “I don’t believe in cost cutting; I believe in cost optimisation. There’s a big difference. Optimisation ensures we maintain quality and efficiency while staying competitive.” It is just like lean manufacturing, it isn’t about doing more with less, it’s about doing more with what matters. K Kulbhushan advocates for removing friction from workflows and making every movement, machine, and minute count. That means proactive maintenance, cross-training staff, and aligning people’s skills with where they create the most value. Quality improves when waste, in all forms, is eliminated. “Every movement, machine, and minute should count,” says Kulbhushan, emphasising people and asset productivity as much as cost. His approach removes workflow friction, while Satnam’s structured prioritisation keeps improvements targeted, Vipul looks at it cost optimization process instead of cost-cutting and Prashant’s clarity ensures the right digital tools amplify those gains, “The right digital tools don’t just cut costs, they multiply value. But only if they’re aligned with refined processes and trained people. Otherwise, you’re just putting expensive paint on a shaky wall.”

TFT: With global strategy shifts, especially between the US and India, how should Indian pharma manufacturers adapt their operational and compliance strategies to stay competitive?

GH: The US is doubling down on advanced manufacturing and reshoring. India can’t compete on speed of adoption alone, but it can lead in smart, cost-effective adaptation, and probably high time to revive ‘Make in India’ campaign. This means keeping quality uncompromised while leveraging scale, cost advantage, and now, a tech-enabled manufacturing mindset. Vipul added, “In the current US–India dynamic, we need to simplify processes instead of overcomplicating them. The future will likely bring a progression from automation to digitisation to full digital transformation, but also, a shift in India’s pharmaceutical focus from generics to big data.”

TFT: You are also organizing Pharma Manufacturing and Automation Excellence Awards 2025. Please tell about that and while gathering information about this I came across a word called F.A.S.T. what does that mean?

GH: Yes, the awards are our way of recognising trailblazers in the pharma space. F.A.S.T. stands for Future-Ready, Automation, Sustainability, and Talent creation/development inspired from Vipul’s thoughts, “Talent isn’t created at the end of the journey; it’s built from day zero. If you want your people to adopt change effectively, you must design your transformation with their actual pain points in mind. Miscommunication vanishes when you have true inclusiveness, from defining requirements to final deployment.” Inspired from key leaders who are transforming pharma as we speak, these are the pillars we believe will define the next decade of pharma manufacturing. The awards honour both individuals and organisations who excel in these areas, proving that excellence is not an act, but a consistent habit.

TFT: Looking ahead, what are the emerging trends in pharma manufacturing that excite you the most, and which ones do you think are overhyped?

GH: Tech can’t be exciting or overhyped, it’s all about how users interact with it based on their customised needs. Exciting- Integrated data platforms that truly connect shopfloor, lab, and QA data in real time, breaking down silos without massive infrastructure overhauls. Overhyped: Buying AI without having clean, usable data. That’s like buying a sports car without fuel, it looks great, but it’s going nowhere. While both kinds of tech are useful, but when, why, and how it is getting implemented is going to make all the difference. Prashant Sharma urges leaders to “clear the fog” by differentiating between automation, digitisation, and transformation, while Satnam Singh Loomba offers his four-step lens: Critical (act now), Vital (plan soon), Essential (future readiness), and Desirable (beware of chasing shiny objects). This prevents what Kulbhushan calls “ill-planned adoption,” where tech is bolted onto shaky foundations, while Vipul suggests inclusiveness of operators and supervisors to focus on the areas, leadership might miss, and Geena highlights the importance of maintaining a balance with sustainability solutions to render better disease free world, and she added, “Leaders need to focus through an EHS lens, saving non-renewable resources, advocating sustainability, and learning from other industries to keep evolving.” All leaders are not rejecting tech adoption, they request companies to understand it, get ready, make changes based on the customised needs of the organisation in question, and create a culture of trust and continuous learning.

TFT: If you could give manufacturing leaders one practical takeaway to implement tomorrow that would deliver measurable results within 90 days, what would it be?

GH: Audit your processes before your regulators do. Map every step, find redundancies, and fix them. You’ll save time, improve morale, and reduce compliance risk, all without a single new piece of equipment- a common piece of advice by every well-known reputed leader I have met and interviewed.

TFT: What are your future plans in other verticals Eminence is exploring?

GH: We are expanding the conversation beyond borders, exploring collaborations in GCC, MENA, and Europe, and adding formats like LinkedIn Live series to make knowledge accessible year-round. Our aim is to make Eminence Business Media the go-to platform for meaningful, results-driven industry engagement.

TFT: Lastly, any message for our readers?

GH: In pharma, just like in life, the difference between surviving and thriving is the willingness to adapt. Don’t just chase buzzwords, refine your processes, empower your teams, and then let the tech amplify your success. And of course, join us this October in Hyderabad, where we’ll be Lean, Clean, and Digitally Mean together.